Knowing exactly how much fish a Purse Seiner really caught is not an easy task… nor for industry or for the for the fisheries authorities. Traditional scales are impossible to use on board, and the priority is getting to fish into low temperatures as soon as possible, since is fundamental for food safety and quality, particularly when you have a big set of over 100 ton in the water. So the captains and observers work on estimates… and while they are very good at it… still an estimate, and while a few tons of fish every set may sound like much… they do accumulate over the year among all the fleet.

Only once the fish is unloaded for “weight in” generally at the cannery, or sometimes before containerisation at port do we get to know the real/verified weights. Yet, this event happens weeks or months after the catching event, and the data (if it makes it back to us in the pacific) could take even more time.

The less time we have in between harvest events and the more accurate weights information, the better for all. Since weights per specie are fundamental and benefit all sorts of fisheries decision making, just to name a few: crew and skipper (catch shares on top of salaries), vessel managers (profitability and insurance), carriers (liability/insurance/payments, etc), science and regulators (stock assessments, target and reference points, under and miss reporting, etc) so… the more accurate the data, the better decision making.

But how can we do that before the fish leaves the region? Well, a Purse Seiner catches and carries about 800 to 1700 metric tons depending it size and age, and then it can take up to a week to transfer their catch to a carrier. It’s a slow process involving putting the frozen fish in nets on deck of the Purse Seiner and hoisting it into the carrier with a crane.

I been thinking for a while that by weighing each the of the nets with frozen fish being moved across to the carrier we could get a much better estimate of the true volumes caught, and the work of the transhipment monitors could focus more on species composition than estimating the weights of the nets to the nearest 100 or 50Kg .

So I came with the idea of determining the weights using hanging crane type scales (called dynamometers) with wireless remote weight display attached to the hooks of the cranes used during the operation, as an opportunity to record accurate transhipment weight data and eliminate the challenges and issues relating to estimates. I played a bit with a couple of of very cheaps ones (220USD) here in Majuro and in Tarawa with quite good initial results, so it was time to get serious about it.

testing “el cheapo” a few months ago

So with the usual support of my friend (and kind of older brother) Hugh Walton from FFA and the usual operational support of my colleagues here MIMRA, I presented a project proposal to FFA and SPC to research the feasibility of the concept and to evaluate what type of hanging crane scales will do the job best.

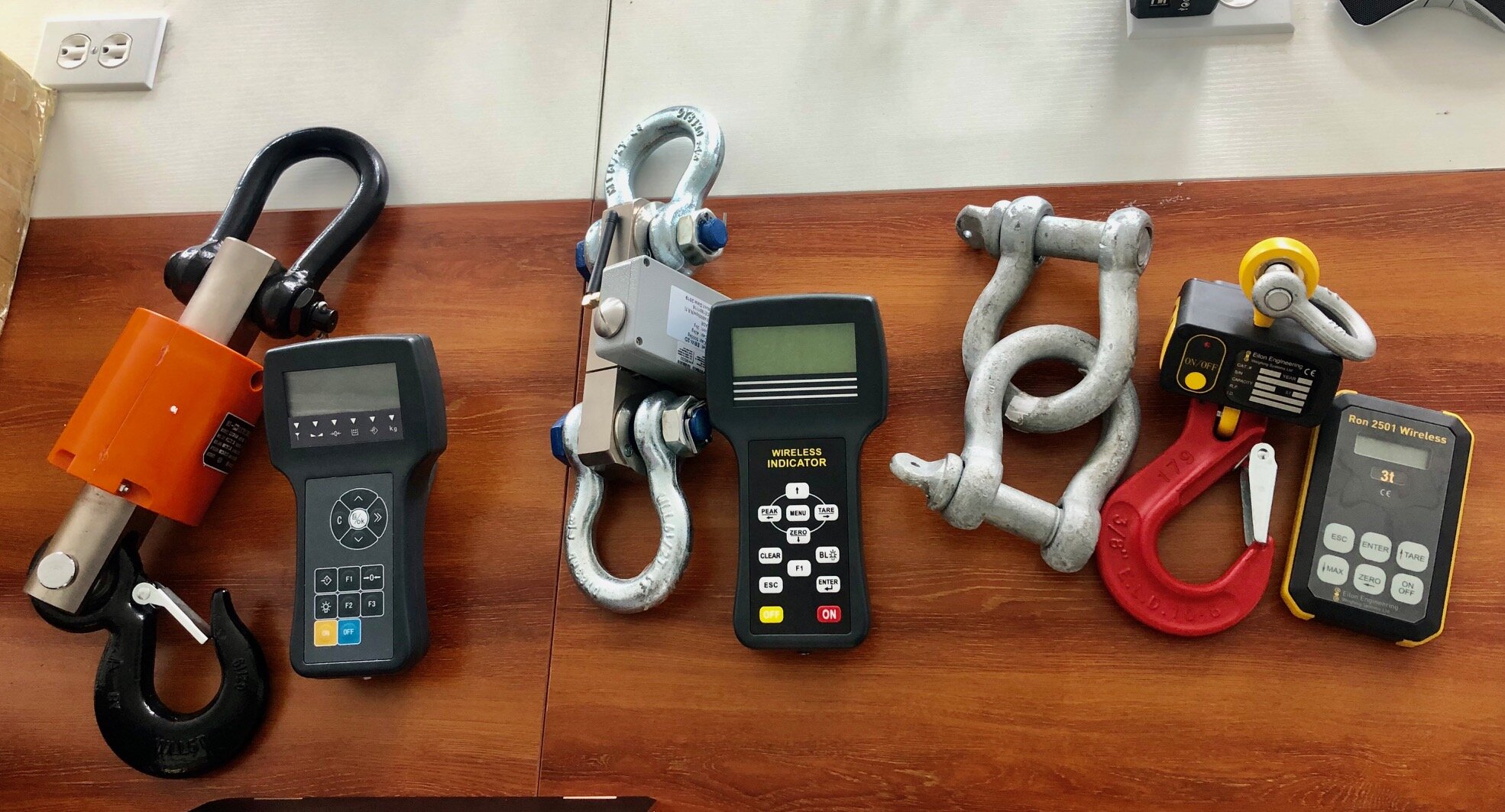

Everyone was on board with the idea, and as a result, I spent quite a lot of time looking at crane scales and we decided to buy 4 different models, and then last week, as a team with Feral Lasie FFA’s PEUMP MCS Adviser, Malo Hosken SPC’s EM /ER Specialist (and good friend), plus MIMRA’s legends Beau Bigler and Melvin Silk (all in the pictures below), we tested the 4 different types of remotely operated electronic crane scales during the transhipment of the locally flagged PS Marshalls 201.

We evaluated each model against attributes such as precision, robustness and ease of use, battery performance / recyclability, price and connectivity, to name a few. And we are all quite happy… besides playing with amazing tech it was great to work with very professional yet relaxed crew… I personally totally loved it

Being Majuro the busiest transhipment port in the world and MIMRA one of the most forward-thinking fisheries administrations in the Pacific, it was just was the logical choice to do this research here. The results would benefit not only RMI, but the whole region as there is transhipment activity in Kiribati, FSM, Tuvalu, PNG and Solomons.

Now that we proven the concest and chosen the best scale, we will continue the work in 2020 with the general aim of standardising their use for monitoring the weights all tuna transhipped in the region, but equally important to improve the operational management and data acquisition process of the port monitor operations, using Majuro as the bussiest scenario.

The good thing about the job is that also it oppen other ideas of things that could be done on board (like putting one of these babies on the brailer, to check the weight comming on board) and many more that I shall write about once the report is approved by all parts

On weeks like this one, I think I have the best job in the world